Prototypes by SSS’AA Lugano students, created with LATI and eXgineering, on display at Rossana Orlandi Gallery

3D Printing Meets Circular Design: Swiss Innovation Takes the Stage in Milan

At Milan Design Week 2025, the spotlight turned to an unprecedented collaboration between LATI3Dlab, eXgineering, and the Higher Vocational School of Applied Arts (SSS’AA) at CSIA Lugano.

As part of RoCollectible 2025, three modular 3D-printed furniture prototypes, born from a creative and technical educational project, were exhibited at the prestigious Rossana Orlandi Gallery.

Designing the Future: Recycled Materials and Large-Scale 3D Printing

At the heart of this initiative was a sustainable design and additive manufacturing workshop launched in September 2024. Second-year Product Design students from SSS’AA worked side-by-side with industrial 3D printing specialists from eXgineering and LATI3Dlab, LATI’s R&D hub for advanced 3D printing materials.

The goal? To explore modular furniture design using reinforced recycled thermoplastic polymers and large-format 3D printing technologies. The result is a collection that merges Swiss-made design with circular principles and cutting-edge 3D printing materials.

Three Projects, One Language: Versatility, Sustainability, Modularity

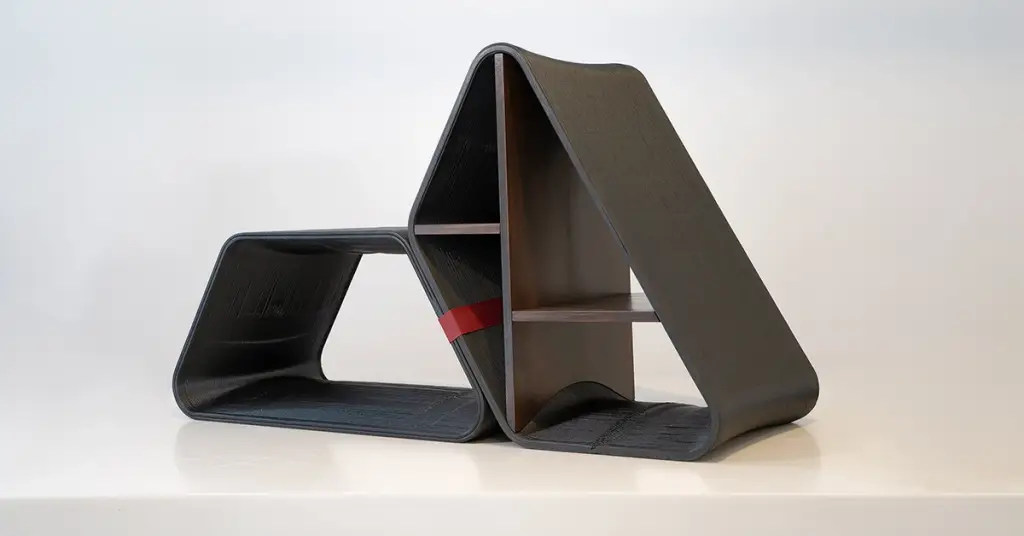

HIVE A seating and storage system composed of semi-hexagonal modules connected by a functional strap. Its flexibility makes it suitable for various environments, from home interiors to public spaces.

RIVIA A modular structure made of interlocking curved elements, featuring wooden pins that allow for easy customization. Perfect for creating bespoke benches, tables, or storage units.

NEBULA

A chaise longue that transforms into a wall-mounted shelf. Lightweight and adaptable, it brings comfort and functionality to a dynamic living space.

All projects were created using technical compounds that are partially or entirely recycled, proving that aesthetics and high performance can go hand in hand with sustainable materials.

A Virtuous Network of Plastics Industry, Education, and Innovation

“Our goal was to show students how an academic project can evolve into a real-world market product,” – François Croci, Head of Training, SSS’AA Lugano.

The intentionally low-tech approach excluded the use of AI, giving space to hands-on design and critical thinking. Students experienced a fully immersive process, from concept and rapid prototyping via 3D printing to public presentation.

“It was an honor to provide advanced tools to bring their ideas to life,” – Simone Maccagnan, CEO of eXgineering.

eXgineering provided its unique RAM (Robotic Additive Manufacturing) technologies, which enabled the swift transformation of untested concepts into tangible, functional objects, ensuring high quality and fidelity between the digital model and the physical prototype, despite tight timelines and the use of specialized materials.

“We worked with complex recycled materials, and the experience was mutually enriching,” – Francesco Manarini, Product Development Manager, LATI.

LATI3Dlab supported every phase of the material selection and provided them free of charge. Special care was taken to verify the origin and quality of the recycled polymers, no small feat, by developing high-performance formulations specifically suited to FGF (Fused Granulate Fabrication) 3D printing for design components.

The three project partners worked in perfect synergy, harmonizing and enhancing the trio of core elements, materials, design, and technology, optimizing each in relation to the others with speed, expertise, and passion.

Explore the Same Sustainable Materials Used in These Designs: